The information on this page worked for me. I may not work for you. This information is provided as-is. Use at your own risk. You should have experience with basic electrical wiring. You should also own a multimeter and a soldering iron.

Important POE info for 10/100M ethernet

lan cable function

Pin 1 <-> data

Pin 2 <-> data

Pin 3 <-> data

Pin 4 <-> DC Positive Wire 1

Pin 5 <-> DC Positive Wire 2

Pin 6 <-> data

Pin 7 <-> DC Negative Wire 1

Pin 8 <-> DC Negative Wire 2

Voltage: 48V max (if you want to go that high you need to make sure your equipment will accept it)

Current: 350ma (500ma max)

Simple POE Injector

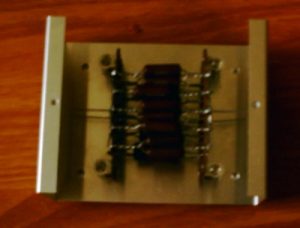

For my POE project I will be using couplers that snap appart. These couplers have RJ45 plugs. These things are not rated for 100mbit but should work just fine.

First break appart the connectors. Use the table above to determin which wires in the connector we need. For me it was red, green, white, and brown. There is a wiring standard that covers the wire colors so most likely you will cutting the same wire colors. Cut the wires as close to the RJ45 connector as you can. Strip the wires back 1/4 of an inch. When done one half will be missing some wires and the other half will have wires for making connections. Twist together the ends of the red and green wires. Then twist together the ends of the white and brown wires. Do the above for both connectors.

If you’re like me you’ve got a collection of AC wall warts. If you don’t start collecting now. Also if you don’t you’ll be hacking on your wall wart that came with your access point.

Next we need to cut a notch in the plastic housing for the power cable. Notch the half that has the extra wires. The notch should be large enough to allow the wires to pass through when the connectors are put back together.

This completes the prep work for using the injector on your projects.

An Example: POE for the D-Link DWL900AP+

The AC adaptor DWL900AP+ is 5V. The unit has a built in voltage regulator capable of accepting up to 36V. A search through my adaptor collection yielded a 9V adaptor with the correct size and polarity connector. The unit ran fine with the adaptor connected. My adaptor had a white line on the cable wire marking the positive wire. Cut the cable 4 to 6 inches from the end. Unzip both cables back 1/2 of an inch. Strip the wires back 1/4 of an inch. Connect the positive wire to the red and green wires. Connect the negative wire to the white and brown wires. Do this for both conectors. Solder the wires and cover with electrical tape. Re-assemble the couplers. Lable the coupleers so you know which connector goes to the equipment/switch and which connector carries the power. Test the setup by connecting a lan cable between the injectors and measure the voltage on the power jack. If everything is OK plug the power jack into the DWL900AP+ to verify its operation. If it all tests good then you are ready to deploy.

The POE/DWL900AP+ deployment was very successfull. The cable lenth is around 50ft. Testing so far has shown no negative impact. Now when the power goes out I still have wireless access for my laptop.

Conclusion

POE can be very usefull. It sure beats putting UPSes all around the house.